Technically speaking, having a true “ULPA” (ultra-low-particulate air filtering) gas mask is impossible.

But that doesn’t mean a gas mask can’t provide ULPA protection.

Because when it comes to designations, certifications, and standards—all of that is left up to the bureaucrats who make the rules.

Accordingly, HEPA and ULPA standards are maintained by the Institute of Environmental Sciences & Technology (per IEST-RP-CC001: HEPA and ULPA Filters). The IEST, meanwhile, sets the standards that labs use to test their filters. But those standards only apply to HVAC filters, like the kind in your air conditioner.

Regarding American-made gas masks and personal respirators, those standards are set by NIOSH (the National Institute of Occupational Safety and Health), in keeping with specific federal regulations (42 CFR Part 84).

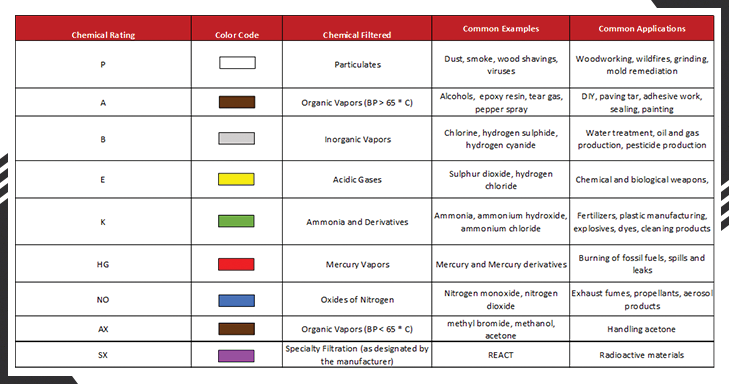

(Image courtesy of UCS)

With all of this in mind, it’s easy to stumble down a rabbit hole of rules and regulations that go on forever.

So it’s important to remember—the regulations might be different, but the science will always be the same. That means that once you understand the certifications, you’ll know exactly what kind of protection you’re getting, no matter how it’s branded.

Now, onto some common particulate threats and the best air filters to address them…

Table of Contents

-

01

Nine Most Common Particulate Threats

-

02

Comparing the Performance of HEPA vs. ULPA Filters

-

03

P3: Uncompromising Particle Filtration

-

04

NIOSH vs CE Certification for Gas Masks & Filters

-

05

The Best Particle Protection for the Money

-

06

Caveat Emptor

Nine Most Common Particulate Threats

Particulate matter (PM) refers to tiny solid or liquid particles suspended in the air.

Those particles can contain anything from nuclear fallout in the aftermath of a reactor meltdown… to deadly viral pandemics… to chemical warfare agents or toxic industrial chemicals. As a result, adequate particulate protection is the cornerstone of any working PPE protocol. It’s not just about making sure you breathe clean air.

(Image courtesy of Kaiterra)

Note that particulate threats are typically categorized by either size or origin, with a few primary categories to keep in mind:

1. Fine Particulate Matter (PM2.5): As the name implies, this classification includes a diameter of up to 2.5 micrometers. These particles are so microscopic, in other words, that their inhalation can draw them deep into your body’s respiratory system. A common air pollutant, they are produced by various sources, including combustion processes, industrial emissions, and natural events like wildfires and dust storms. Automotive emissions, mainly from diesel engines, are a primary source of PM2.5 particulate.

2. Coarse Particulate Matter (PM10): This includes all particles between 2.5 and 10 micrometers in size. Though these particles are substantially larger, they can still cause trouble for your respiratory health. Primary sources include construction activities, road dust, agricultural operations, and natural sources such as pollen and sea salt aerosols.

3. Dust and Soil Particles: Though most people overlook the threat of inhaling everyday dust and soil, the damage can add up over time—as we covered in our recent article on sawdust inhalation. Additionally, dust storms, wildfires, and other disasters (both natural and manufactured) can leave fine dust and soil particles suspended in the atmosphere.

4. Industrial Emissions: Another everyday threat comes from factories and power plants that burn fossil fuels, emitting particulates as a byproduct of combustion. These emissions, notably, can contain toxic substances such as heavy metals, which can settle on the ground or become airborne, posing risks to human health and the environment. In particular, coal-fired power plants are notorious for ejecting large amounts of PM 2.5 and PM10.

5. Construction and Demolition Activities: Construction and demolition activities generate airborne particulates through cutting, grinding, and excavation. Dust generated during these activities can contain hazardous materials such as asbestos and lead, posing significant health risks to workers and nearby residents if not adequately controlled.

6. Indoor Air Pollution: Even inside the home, where most Americans assume they’re safe, you can still be exposed to particulate threats. After, everything from secondhand smoke to cooking fumes and burning candles can cause pollution that accumulates over time and negatively affects indoor air quality, leading to health problems for occupants.

7. Microplastics: After decades of pollution, our environment has become increasingly filled with refuse in the form of microplastics. These particles are typically less than 5 mm in size, resulting from the breakdown of larger plastic waste, shredding of synthetic clothing fibers, or even the microbeads infused in some personal care products. Significantly, recent testing has found microplastics in every aspect of human anatomy—even in the placenta of newborn babies.

8. Airborne Viruses and Pathogens: Airborne viruses are among the most consistently deadly particulate threats on the planet. They often travel suspended in microscopic droplets, ejected by a sneeze or a cough from someone infected. From there, they can spread to infect countless victims depending on the virality and deadliness of the pathogen involved.

9. Radioactive Particles: In the aftermath of a nuclear explosion or a reactor meltdown, debris is often pulverized and then ejected into the air by the explosion. Some pieces will fall back to earth immediately. Still, ultra-fine irradiated particles can coast on the wind for dozens, sometimes even hundreds of miles after being shot into the atmosphere. When people refer to “fallout,” they’re talking about these exact particles—and they’re loaded with radioactive isotopes like Iodine-131 (which frequently causes thyroid cancer).

Obviously, all particulate threats aren’t created equal.

Instead, it’s important to consider these threats in terms of toxicology. Some can be dangerous even in extremely small doses, like nerve agents or deadly viruses. But others can still have a serious impact on your health if you’re consistently exposed to high doses (like construction debris or PM2.5 particulate).

Comparing the Performance of HEPA vs. ULPA Filters

Particle filtration is the process of trapping and removing solid or liquid particles from the air, ensuring that the inhaled air is clean and safe. This filtration process is vital in various contexts, from industrial settings to healthcare, construction, and everyday life.

Effective particle filtration helps prevent respiratory illnesses, allergies, and exposure to hazardous substances.

HEPA and ULPA are two of today’s most popular filtration standards, which you’re most likely to see in advertisements and on store shelves.

Since the 1940s, HEPA filters have established a reputation as the gold standard in air filtration; they capture an extensive array of particles—from dust to pollen, pet dander, and even bacteria or viruses. Their high filtration efficiency is largely attributed to their effectiveness.

IEST standards dictate HEPA filters—to differentiate them from standard air filters, must achieve a filtration efficiency that eliminates at minimum 99.97% of particles measuring 0.3 microns or larger in size from the passing air; this rigorous level sets these specialized filters apart.

(Image courtesy of Air Innovations)

Putting this into perspective: a particle measuring 0.3 is microscopic. That means that even when compared to a human hair, it’s approximately 300 times smaller. Despite their tiny size, however, HEPA filters demonstrate exceptional precision in trapping these minuscule particles; indeed, they contain them with remarkable accuracy.

ULPA home air purifiers commonly utilize these filters, as they actively eliminate allergens and other contaminants from the air, thereby facilitating cleaner—and ultimately healthier—indoor environments.

Various commercial settings, particularly hospitals and cleanrooms, also rely on HEPA filtration for its popularity. This is because it maintains a sterile environment and prevents the spread of airborne diseases.

They’re even used in aerospace applications, where precision engineering necessitates the cleanest environment possible.

Regarding PPE, HEPA protection corresponds closely with N95 masks, which can similarly filter out particles as small as 0.3 microns. Though that’s adequate protection for many healthcare and occupational applications, it’s not enough to address some of the most severe biological threats.

That’s where ULPA filtration comes in.

Filters are designed to remove at least 99.9995% of particles with a size of 0.12 microns or larger from the air. This remarkable efficiency means that ULPA filters can capture particles much smaller than HEPA filters can handle.

As such, ULPA filters are utilized in environments with paramount cleanliness and contamination control. They can create a safe environment for the most delicate procedures, from semiconductor manufacturing cleanrooms to hospital operating rooms, nuclear facilities, and research laboratories.

When it comes to HVAC filtration, ULPA filters provide the highest level of protection you can get. And it’s only logical to look for the best, as long as it falls within your budget.

So, what’s the equivalent particle protection for PPE?

P3: Uncompromising Particle Filtration

P3 particle protection is the highest level of respiratory protection as determined by the CE (Conformité Européenne).

The classification means a filter or respirator can capture at least 99.95% of airborne particles as small as 0.3 microns, making it effective against a broad spectrum of contaminants, including dust, smoke, pollen, bacteria, and viruses. The exact standards are in CE references EN 143 and EN 149.

Unlike disposable or cloth N95 masks, P3 filters are almost always used with half-face or full-face respirators and gas masks. And you’ll find P3 respirator filters in the same places where ULPA filters handle the air. Namely:

-

Healthcare: In healthcare settings, P3 filtration is essential for protecting medical professionals from exposure to airborne pathogens, including bacteria and viruses. Respirators with P3 filters are used during procedures that generate aerosols, such as intubation and ventilation.

-

Industrial Environments: P3 filtration is deployed in industries where workers are exposed to hazardous particulates, such as construction, mining, and manufacturing. It shields workers from dust, fumes, and fine particles that could lead to respiratory ailments.

-

Laboratories: Laboratories dealing with hazardous substances or biological agents rely on P3 filtration to maintain a safe working environment. This level of filtration ensures that potentially harmful particles are contained and filtered out of the air.

-

Construction and Demolition: Workers in construction and demolition activities often encounter airborne dust and debris. P3 particle filtration in respirators keeps the air they breathe free from harmful particles.

-

Agriculture: In agricultural settings, P3 filtration can protect workers from inhaling dust, pollen, and other agricultural allergens. This is particularly important for individuals with allergies or respiratory sensitivities.

-

Pandemic Response: P3 filtration was crucial during the COVID-19 pandemic. Accordingly, respirators with P3 filters were used by healthcare workers and first responders to protect against the inhalation of the SARS-CoV-2 virus.

Achieving P3 particle filtration efficiency involves combining innovative design and advanced materials.

These filters typically use a specialized filter media composed of synthetic fibers, such as polypropylene or fiberglass, arranged in a dense, intricate network. And they use a combination of filter media with varying pore sizes. This multi-layer approach ensures that particles of different sizes are effectively captured at different stages of filtration.

There’s only one reason you don’t see P3 masks everywhere across America. Regulations.

Remember: the National Institute of Occupational Safety and Health regulates American gas masks and respirators. They work closely with OSHA (the Occupational Safety and Health Administration) to establish respirator regulations.

As a result, professionals are required to use a NIOSH-certified respirator on the job site. Even when P3 filtration is just as effective, on-the-job PPE is still a matter of insurance and regulatory compliance.

But once again, the devil is in the details…

NIOSH vs CE Certification for Gas Masks & Filters

NIOSH sets stringent filtration standards for American respirators and gas mask filters.

These standards ensure that NIOSH-certified gas mask filters protect users from hazardous airborne particles, including those in industrial, healthcare, and emergency response environments.

NIOSH standards. (Image courtesy of Parcil Safety)

The "CE" (Conformité Européenne) marking is a certification mark that indicates conformity with European Union (EU) health, safety, and environmental protection standards.

CE certification is widely recognized in the European Economic Area (EEA) and other regions that follow EU regulations. Regarding gas mask filters and respirators, CE certification signifies compliance with European standards for respiratory protection.

CE certification for gas mask filters and respirators involves compliance with European standards such as EN 149:2001+A1:2009. These standards classify respirators based on their filtration efficiency and performance. Common CE respirator classifications include:

-

FFP1: Filters out at least 80% of airborne particles.

-

FFP2: Filters out at least 94% of particles.

-

FFP3: Filters out at least 99% of particles.

Ultimately, CE certification is essential for individuals and industries operating within the European Union and other regions that recognize CE standards.

CE standards. (Image courtesy of Parcil Safety)

Where American professionals are required to use NIOSH-certified masks, CE certification is essential to comply with EU regulations. Note that NIOSH certification is notoriously lengthy and costly, with NIOSH-certified respirators designed exclusively for on-the-job usage. Plus, American-made military gas masks (like the Avon M50) are virtually inaccessible for civilians and even most contractors.

Fortunately, there’s a better alternative…

The Best Particle Protection for the Money

MIRA Safety P3 ParticleMax filters come in packs of six, with ultra-lightweight construction that provides the highest level of protection from airborne particulates.

The CDC (Centers for Disease Control) has even developed standards and practices for reusing these types of filters, provided that exposure has been limited. As a result, just one pack of filters could provide weeks of protection for each family member.

P3 particle protection is also a requisite for protection from nuclear fallout. Of course, your filter will also need the “REACTOR” certification to protect you from radioactive isotopes like iodine-131 that are commonly found in the atmosphere following a nuclear meltdown or attack. In that case, you’ll want a filter like the NBC-77 SOF.

With the NBC-77 SOF, you’re getting the highest level of protection from the full range of CBRN threats. As such, this filter protects the user from chemical weapons, biological threats, and nuclear threats—at the highest tested concentrations. Additionally, the filter has a twenty-year shelf life in its original packaging. So, it lasts far longer in storage than the average filter.

Finally, the absolute best value in particulate protection comes with an investment in potassium iodide tablets.

These tablets are designed for a single, simple purpose: They flood your system with safe iodine, preventing you from absorbing any of the radioactive isotope Iodine-131, which (once again) can cause thyroid cancer. All in all, it’s a straightforward yet highly effective step to protect yourself from nuclear fallout—even if you’re hundreds of miles from ground zero.

Caveat Emptor

In the past, we’ve written about how cheap gas masks and filters can end up costing you a fortune. That’s because there can be serious health risks associated with wearing “cheap” expired or surplus PPE. Some expired Russian gas mask filters even contain asbestos!

But the opposite is true, too. You can, for example, potentially spend a fortune on personal protective equipment, all while getting about the same level of protection one could get for 1/10th the price. It’s all about understanding the different types of certifications and the potential threats you might face.

For professionals in the United States, there’s no choice but to use NIOSH-certified equipment. But for everyone else (including members of the US Department of Defense, who are clients of MIRA Safety), CE-certified masks can be a practical and affordable alternative that doesn’t compromise on protection.

P3 gas mask filters, meanwhile, provide the highest level of particulate protection—corresponding with the ULPA filters used in cleanrooms, nuclear facilities, and semiconductor fabrication plants. When the same filters are reactor-certified, you can trust them to protect you from nuclear fallout.

Getting this level of protection from NIOSH-certified filters and respirators can be difficult by comparison. And it could cost a fortune. But if you know what type of protection you’re looking for—and you know where to get it, you can save a fortune.